Yields Strong Seamless Connections!

Laser Welding is now available to the dental laboratory.Producing higher quality restorations in less time than conventional soldering and welding, laser welding simplifies many laboratory procedures while providing all of the benefits of advanced technology.

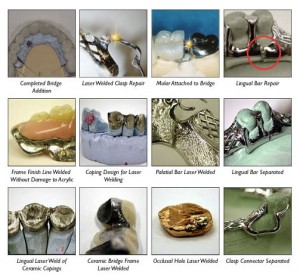

In the dental laboratory, laser technology is used for constructing and repairing the metal components of cast partials, attachments, bridges and implants.Because metal, acrylic and porcelain can be distorted or damaged by conventional soldering and welding, making repairs has, up until now, required us to rebuild the prosthesis. Laser welding eliminates this time-consuming process. Among other alterations, we are now able to add teeth and saddles, restore worn out clasps and reconstruct broken major and minor connectors, all without removing acrylic or teeth.

The highly focused light beam produced by a laser can melt metal with pinpoint accuracy while generating very little heat. This ability yields multiple benefits. Microscopically precise connections can be made, even in close proximity to complex parts, because little to no heat transfer occurs during the joining process. In addition, laser welds can be made directly on the master model, thus maximizing accuracy and reducing remakes.

Another feature that contributes to the accuracy of laser welds is increased control of thermal expansion variables. Unlike soldering which introduces foreign alloys that can create inconsistencies in thermal expansion, a laser welder makes parent metal connections. Distortions are less likely to occur during the welding process since expansion coefficients of the metal and porcelain remain consistent. Using parent metals rather than foreign alloys also reduces the risk of allergic and galvanic reactions.

Laser welding yields strong, seamless connections. Research indicates that laser welds are 260% stronger than traditional solder joints, 43% stronger than microplasma welds and 95% as strong as the original alloy (LMT, June/July 1995). Although stronger, laser welds are less bulky than traditional solders. As a result, they provide greater patient comfort.

Laser welding improve the quality and fit of our restorations, we have been able to reduce turnaround time for repairs and corrections since we can, in some cases, now make alterations to appliances more easily. Laser welding is fast becoming an essential part of today’s dental laboratory. The reasons are simple it is quicker, easier and produces better results.